Getting My China Injection Molding To Work

Wiki Article

Some Known Details About China Injection Molding

Table of ContentsExcitement About China Injection MoldingChina Injection Molding Things To Know Before You BuyNot known Details About China Injection Molding The smart Trick of China Injection Molding That Nobody is DiscussingChina Injection Molding Fundamentals ExplainedExamine This Report about China Injection Molding

The packaging of material in the shot stage allows added material to stream into the mold and mildew and also decrease the amount of noticeable contraction. The mold can not be opened up up until the required air conditioning time has expired.

When the mold and mildew is opened, a mechanism is made use of to push the dismantle of the mold and mildew. Force needs to be put on expel the component since during cooling down the part diminishes and abides by the mold. In order to promote the ejection of the part, a mold and mildew release agent can be splashed onto the surfaces of the mold and mildew cavity before shot of the material.

Not known Incorrect Statements About China Injection Molding

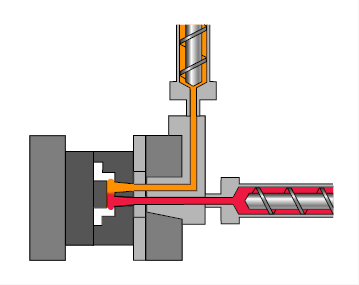

Shot device The shot unit is responsible for both heating and also infusing the material right into the mold. The first component of this system is the hopper, a huge container right into which the raw plastic is poured. The hopper has an open base, which enables the material to feed right into the barrel.

China Injection Molding Can Be Fun For Everyone

This system is usually a ram injector or a reciprocating screw. A ram injector compels the material ahead through a warmed section with a ram or bettor that is usually hydraulically powered. Today, the extra common method is making use of a reciprocating screw. A reciprocating screw moves the product forward by both revolving and gliding axially, being powered by either a hydraulic or electric motor.While it is advanced, the material is thawed by stress, friction, as well as extra heating systems that surround the reciprocating screw. The molten plastic is then infused really rapidly right into the mold and mildew through the nozzle at the end of the barrel by the accumulation of stress and also the forward activity of the screw - China injection molding.

When the product has actually strengthened inside the mold and mildew, the screw can withdraw and also load with even more product for the following shot. Securing device Before the shot of the molten plastic right into the mold, the two halves of the mold should first be securely closed by the clamping unit. When the mold is affixed to the injection go to these guys molding machine, each half is fixed to a large plate, called a platen.

China Injection Molding Can Be Fun For Anyone

The rear fifty percent of the mold, called the mold core, is placed to a movable platen, which moves along the connection bars. The hydraulically powered securing motor actuates securing bars that push the portable platen towards the stationary platen and also exert sufficient force to keep the mold and mildew securely shut while the material is infused and ultimately cools.An ejection system, which is connected to the back half of the mold and mildew, is actuated by the ejector bar as well as pushes the strengthened dismantle of the open dental caries. Device requirements Injection molding equipments are commonly characterized by the tonnage of the clamp pressure they supply. The needed clamp pressure is identified by the forecasted area of the parts in the mold click for source and mildew and the stress with which the material is injected.

Particular materials that need high shot pressures may need greater tonnage machines. The dimension of the component must likewise adhere to various other device requirements, such as fired capacity, clamp stroke, minimum mold and mildew density, and platen dimension. Shot molded parts can differ significantly in dimension and as a result require these steps to cover a large variety.

The 7-Minute Rule for China Injection Molding

5 2 (China injection molding). 95 x 2. 95 40. 55 x 40. 55 122. 0 x 106. 3 Tooling The shot molding process utilizes molds, normally constructed from steel or light weight aluminum, as the personalized tooling. The mold has many parts, however can be split right into 2 halves. Each fifty percent is affixed inside the injection molding device and also the rear fifty percent is permitted to move so that the mold can be opened and also closed along the mold and mildew's parting line.When the mold and mildew is closed, the room in between the mold and mildew core and the mold dental caries forms the component dental caries, that will be loaded with molten plastic to create the wanted component. Multiple-cavity mold and mildews are often used, in which both mold and mildew fifty percents form several similar component cavities. Mold base The mold core and mold tooth cavity are each mounted to the mold and mildew base, which is then fixed to the platens inside the injection molding equipment.

The rear half of the mold and mildew base consists of the ejection system, to which the mold and mildew core is connected, and also an assistance plate. When the clamping device divides the mold and mildew fifty percents, the ejector bar actuates the ejection system. The ejector bar presses the ejector plate onward inside the ejector box, which consequently presses the ejector pins into the shaped part.

The Single Strategy To Use For China Injection Molding

Mold and mildew networks In order for the molten plastic to flow into the mold and mildew cavities, a number of channels are integrated right into the mold style. Initially, the liquified plastic enters the mold and mildew through the sprue. Additional channels, called joggers, lug the molten plastic from the sprue to all of the cavities that should investigate this site be filled. China injection molding.Report this wiki page